Optimize performance and de-risk deployment of new protection schemes and algorithms

Digital simulation allows protection equipment to be subjected to virtually all possible faults and operating conditions in a controlled, flexible environment. Because the simulation runs in real time, protective devices can be physically interfaced to the simulated network in a closed loop.

Benefits of performing HIL testing

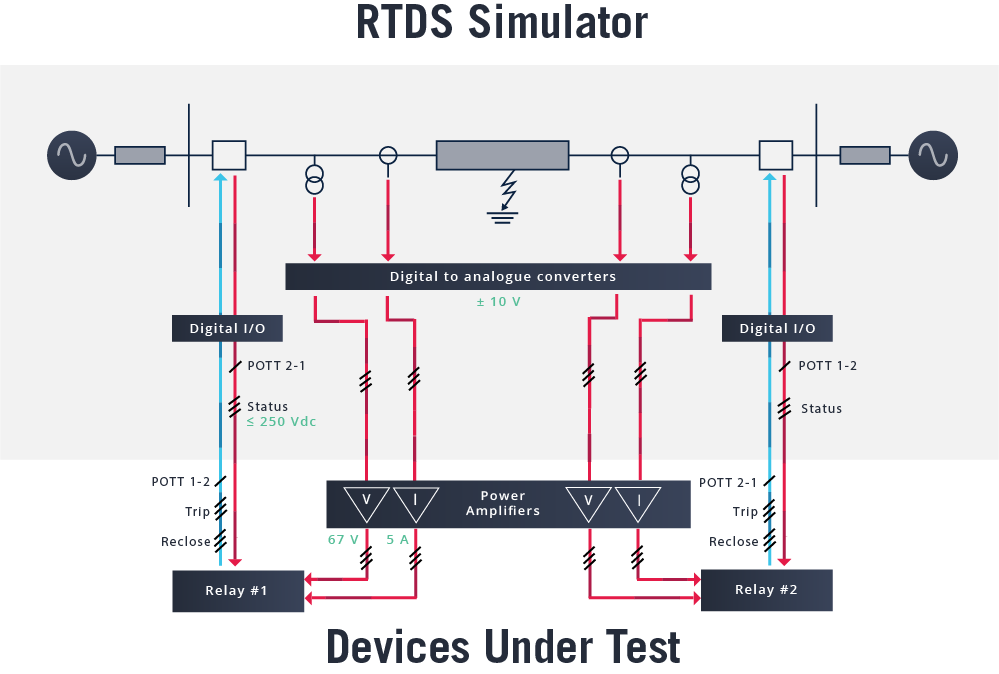

Inside a hardware-in-the-loop testbed for protection devices

Voltage and current signals signals from simulated instrument transformers are sent to the relay via analogue output via the GTAO card or IEC 61850-9-2 Sampled Values via the GTNETx2 card of the RTDS Simulator hardware.

Analogue outputs operate over a maximum range of +/- 10 Vpeak, so to provide secondary voltage and current to the protection equipment, the GTAO output is connected to power amplifiers (or, in some cases, is connected directly to the protection equipment for “low level” testing).

The protection should respond to faults by providing trip and possibly subsequent reclose signals. Since the network model is simulated in real time, the signals from the protection will be used to operate breakers modeled in the simulation via digital input or IEC 61850 GOOSE Messaging.

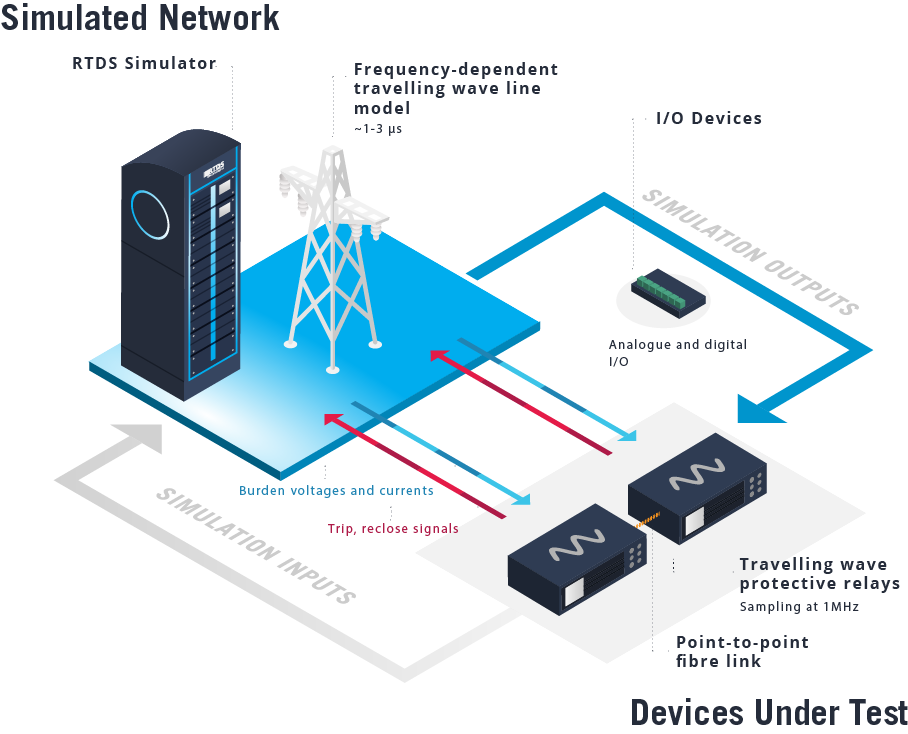

Unprecedented accuracy in Travelling Wave Relay Testing

The RTDS Simulator’s Travelling Wave Relay Testing (TWRT) facilities is the only tool with a Frequency Dependent Phase Domain transmission line model operating at the necessary small timestep for traveling wave testing. The tool and models involved have been specifically designed to accurately represent travelling wave attenuation and dispersion for proper performance analysis of travelling wave protection and fault locating. Learn more in the video below.

Travelling Wave Protection Testing

with the RTDS Simulator

Related Information